The customer

The customer is a private wood processing factory with several log-handling lines, including a sorting and debarking line and a slabbing line. The production lines were prone to different types of bottlenecks, including:

- Emergency shutdowns

- Frequent downtime for unknown reasons

- Shutdowns caused by chips clogging up the log-cutting line

The customer decided to conduct overall equipment effectiveness (OEE) monitoring to investigate the problem and mitigate the shutdowns.

Brimit provided the factory with a system of inductive sensors on the customer’s operation lines to monitor productivity.

Analyzing and monitoring shutdowns

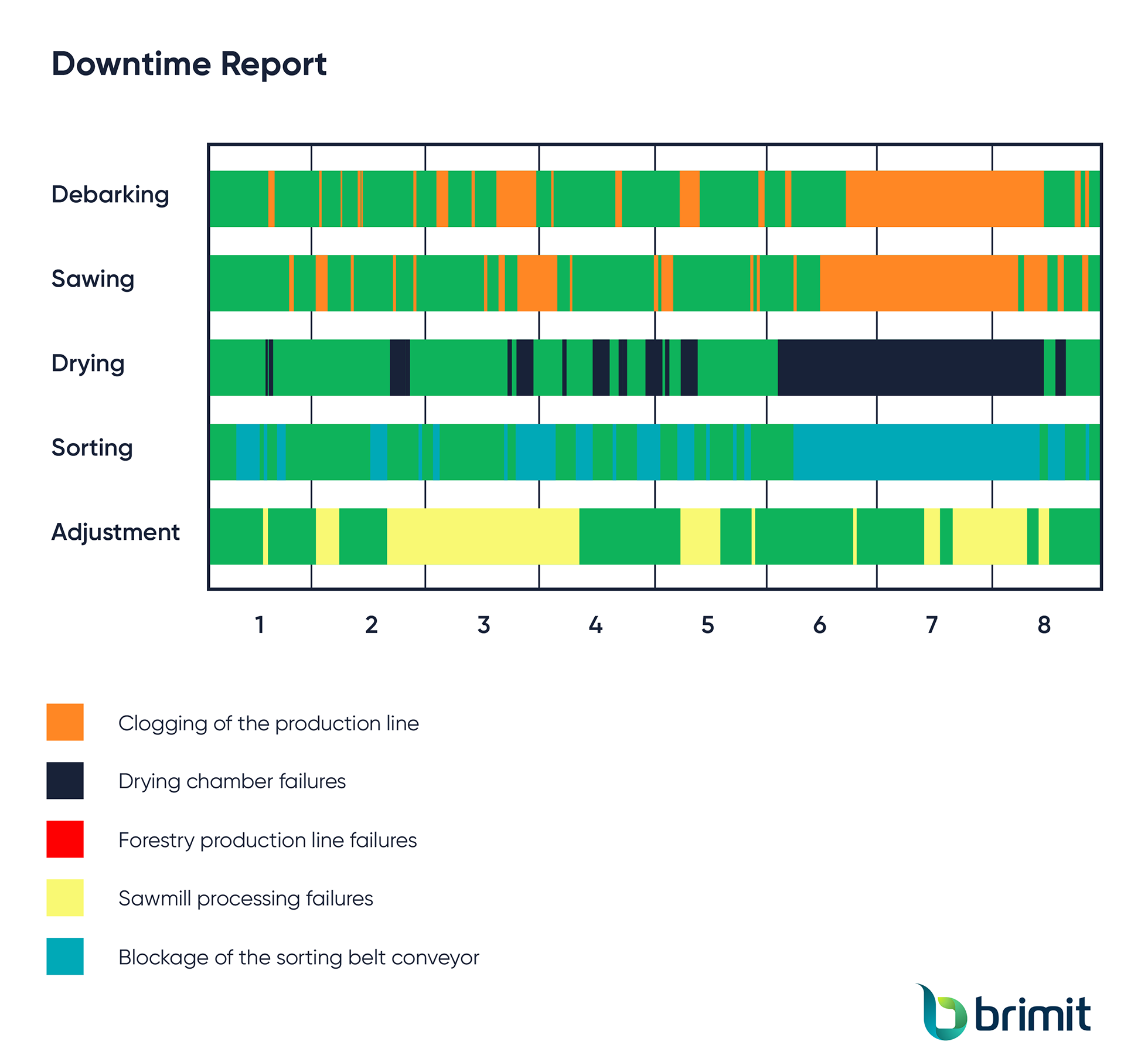

Brimit’s system monitors log feeding and detects occurrences of shutdowns. Production line operation data is gathered in real time and sent to the back-end platform. The OEE data can be accessed via a local website, where a timeline chart is built. The chart shows the line’s operating time with the options to choose from a list of reasons for shutdown or add a reason manually. The data can then be used to analyze the log-handling lines’ productivity.

Brimit’s OEE monitoring solution allows the customer to track the causes of the longest production stoppages.

Preventing chips from clogging up the log-cutting line

To deal with shutdowns caused by chips clogging up the log-cutting line, our sensors detect blockages in the wood chip hopper and automatically send corresponding notifications to the appropriate personnel, who can clean the chambers before a shutdown occurs.

More about Brimit’s OEE monitoring system

The solution includes an inductive barrel-style proximity sensor connected to a module developed by Brimit, which sends data from the sensor to the back end over the Ethernet using the MQTT protocol. The back end is based on microservice architecture and containerization technologies.

The system can also be used in areas such as metalworking, printing, manufacturing of construction materials, and packaging production.

The benefits of Brimit’s solution include:

- No vendor lock-in—Our devices can easily be integrated into a working manufacturing system.

- An intuitive UI—Thanks to the use of a functional block diagram (FBD) language, it’s easy for users without extensive technical knowledge to interact with the data collected.

- Cost-effectiveness—Our system is a standalone solution that can meet different performance and budget requirements and doesn’t involve paying for features that won’t be used.

- Connectivity—Brimit’s OEE monitoring system can be connected with other industrial monitoring systems, such as a vibration monitoring solution.